Ground vibration on construction site

Applications

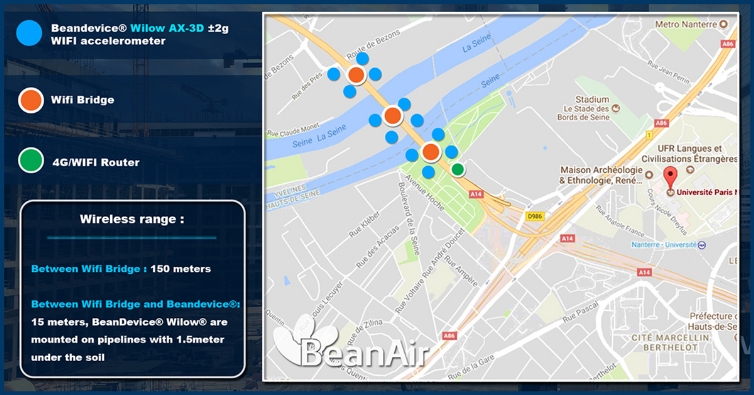

Location: Nanterre, France

Site monitored since: November 2017

OVERLL TASKS

At the beginning, Grand Paris (Greater Paris) is a project to transform the Paris metropolitan area into a major world and European metropolis of the 21st century, in order to improve the living environment of the inhabitants, to correct the territorial inequalities and to build a sustainable city.

During the suburb train line (RER) in Nanterrre, the monitoring work consisted to track ground vibration on gas and water pipeline during construction work alongside the bridge structure.

Caption 1:

Overall view of monitoring site

EQUIPMENT USED

The following materials were deployed on the monitoring site:

• 12 x wireless vibrations sensors (Ref: BeanDevice® Wilow AX-3D) were deployed

• 1 x IOT Gateway with 3G/4G/LTE connectivity provides a remote access

• 1 x BeanScape® RA (Remote access)

BeanDevice® Wilow® AX-3D , Wireless Vibration sensor (acceleration and Velocity)

Due to the low noise, the BeanDevice® Wilow® AX-3D is suitable for Static Velocity Measurement on construction material

OPERATION MODE

• DAQ Mode: Streaming with event-trigger (S.E.T.) with 100Hz of sampling rate

• Alarm thresholds : 1.4G on Z axis and 0.4G on X and Y Axis

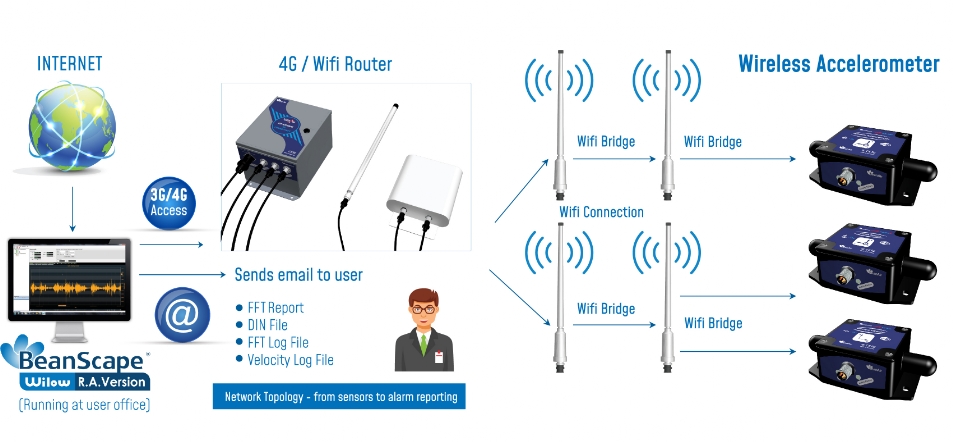

Caption 2: IOT sensors deployment alongside the bridge structure

Caption 3 : Network Topology - from sensors to alarm reporting

Caption 4: IOT Vibration sensor installation on pipeline (BeanDevice® Wilow® AX-3D)

Caption 5: WIFI Bridge is used to extend the wireless range

Caption 6: IOT Gateway with 3G/4G/LTE Connectivity

DAQ MODE CONFIGURATION

Streaming with Event-Trigger (S.E.T.) data acquisition mode Notification Cycle :

Every 10 minutes, the BeanDevice® Wilow® transmits a notification to the BeanScape® Wilow® software

Sampling rate and Data Acquisition duration :

When a trigger is reached, the BeanDevice® Wilow® transmits data measurement to the supervision software for a duration of 10 seconds with a sampling rate of 100 Hz

Datalogger :

Only measurements with a value higher than the threshold are recorded on the onboard datalogger (5 millions Logs)

ONLINE DATA ANALYSIS MODE :

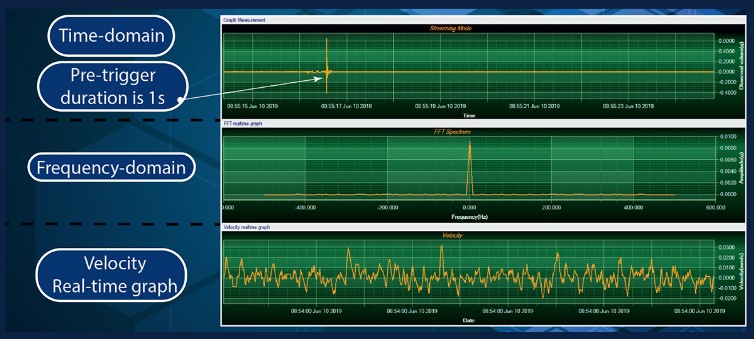

Online Data Analysis Module enables Real-Time FFT and PPV ( Peak Particle Velocity):

• Automatic FFT and PPV reports ( following DIN4150-3 standard)

• Real-Time FFT and PPV display

Streaming with Event Trigger S-E-T data acquisition mode

Signal Processing Module

ALARMS TRIGGER

Caption 9 : Alarms trigger on X Axis

Caption 10: Alarms trigger on Y Axis

Caption 11 : Alarms trigger on Z Axis

Caption 12: Real-Time Velocity and FFT (Fast Fourrier Transform)